A.S. Carpet is one of the most preferred handmade Indian carpet manufacturers. The company has made its presence as carpet manufacturers in Bhadohi, India by providing the best quality carpets all over the world.

The best wool is sourced and processed. We use fine quality of Indian, blended / pure New Zealand wool, viscose, silk, worsted and semi-worsted wool etc.

Raw wool is cleaned and then spun into yarn.

The wool is dyed to over 1200 colors. The dyes used in the production of carpets are eco-friendly and safe for humans.

The process of drying the Wool.

Every carpet is exclusively designed in the studio.

Artisans weave the carpets from a provided carpet map.

Carpets are washed to bring out the natural sheen in the yarns used and dislodge any dirt from the finished weaved carpet.

Carpets are backcoated to make them more durable and readily handle. A good backcoating system serves to anchor the pile and prevent pull-out of the tufts, minimizes loosening of the pile, reduces shedding, provides dimensional stability and prevents fraying during cutting.

Once the yarn is woven into a rug, there are few steps in the final processing of the rugs. Trimming, washing, and drying of the rug – soon after the weaving, the rug is taken off from the loom for its trimming. The surface of the rug is smoothening out by removing extra hanging fibers. Pointed sharp scissors are used for this leveling. This trimming brings out the clarity in the design of the rug. After trimming, the rug is washed with detergent and later with only with clean water to get rid of all the dirt and leftover detergent. Later the rug is left under sunlight for drying for about four-five days.

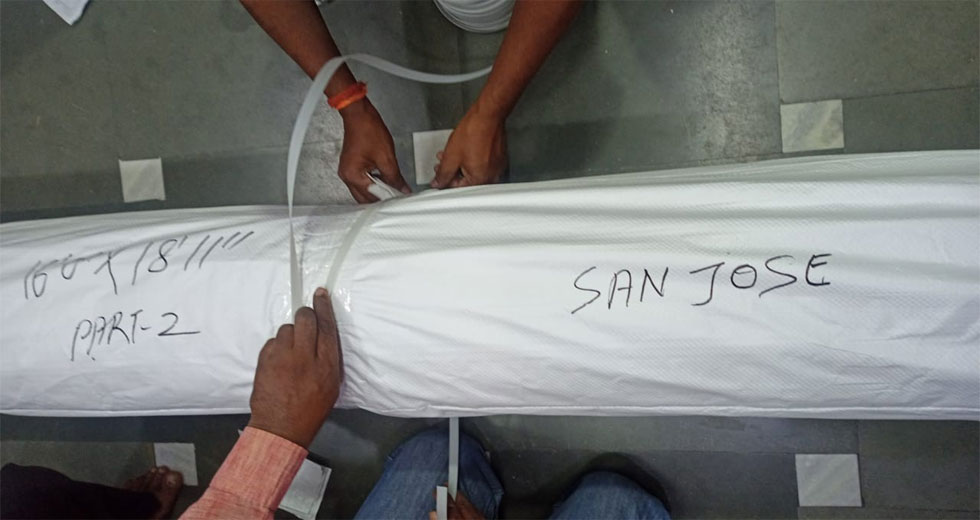

Post the quality conformance, the carpets are packed with the moisture resilient wrapping material with appropriate safety. The packing of the carpets is done in three layers to ensure the carpets do not get damaged while being transported to the prospective buyers.

The finished rug is ready to be purchased by the customers to transform living spaces.

..................................................................................................................

..................................................................................................................